In industrial settings, where harsh operating conditions prevail, the performance and reliability of components become paramount. TIMKEN Bearings have garnered a reputation for delivering exceptional performance even in the most challenging environments. This article explores the outstanding capabilities of TIMKEN Bearings in withstanding harsh conditions and their significance in ensuring optimal operations in such settings.

Robust Construction:

TIMKEN Bearings are designed and built to withstand extreme operating conditions encountered in harsh environments. They are constructed with high-quality materials and undergo rigorous testing to ensure durability and resistance to factors like temperature fluctuations, corrosion, contaminants, and heavy loads. The robust construction of TIMKEN Bearings ensures reliable performance and minimizes the risk of premature failures, making them ideal for challenging industrial applications.

High Temperature Resistance:

In environments with elevated temperatures, such as steel mills, foundries, and glass manufacturing plants, TIMKEN Bearings excel. They are engineered with advanced heat-resistant materials and innovative lubrication systems that can withstand high temperatures without compromising performance. The ability of TIMKEN Bearings to maintain their structural integrity and provide reliable operation in extreme heat environments ensures uninterrupted production and prevents costly downtime.

Corrosion Protection:

Harsh environments often expose bearings to corrosive substances, such as chemicals, moisture, and saltwater. TIMKEN Bearings are designed with protective coatings and specialized seals to combat corrosion effectively. These coatings and seals provide a barrier against external elements, preventing rust, pitting, and premature wear. By maintaining their performance in corrosive environments, TIMKEN Bearings contribute to extended service life and reduced maintenance requirements.

Contamination Resistance:

Industrial operations, such as mining, construction, and agriculture, generate a significant amount of debris, dust, and contaminants. TIMKEN Bearings are engineered with features like advanced sealing systems and effective filtration mechanisms to prevent the ingress of contaminants. By minimizing the impact of external particles on the bearing surfaces, TIMKEN Bearings ensure smooth operation, reduce friction, and prevent premature failure, even in heavily contaminated environments.

Specialized Solutions:

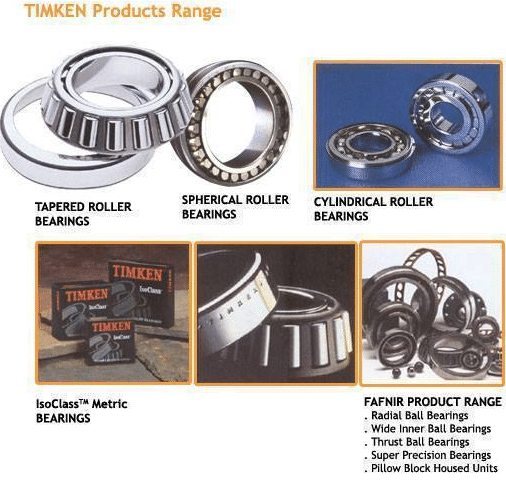

TIMKEN offers specialized bearing solutions tailored to specific harsh environments. For example, in industries where moisture and particulate contamination are prevalent, they provide sealed and maintenance-free bearings that offer enhanced protection. In applications requiring extreme temperature resistance, TIMKEN offers bearings with specialized materials and lubricants to maintain optimal performance. These specialized solutions demonstrate TIMKEN’s commitment to meeting the unique challenges of harsh environments and providing reliable solutions for critical applications.

Conclusion:

TIMKEN Bearings have established themselves as a trusted choice for industrial applications in harsh environments. Their robust construction, high temperature resistance, corrosion protection, and contamination resistance enable them to perform reliably even in the toughest conditions. By utilizing TIMKEN Bearings, industries can minimize downtime, reduce maintenance costs, and ensure optimal performance in challenging operating environments. With their focus on durability, reliability, and tailored solutions, TIMKEN continues to be a preferred brand for industries operating in harsh conditions.

We support more information about Bearings. you can visit https://cmtgbearing.com. or email us info@cmtgbearing.com.

| NSK 170RUBE3102PV | SKF Bearing 7052ACD/P4A |

| SKF FAG INA NSK BEARINGS | VARIOUS BEARINGS SELECTION |