When selecting bearings for industrial machinery and automotive applications, customers consider not only performance but also cost-effectiveness. SKF and TIMKEN are leading manufacturers known for their high-quality bearings and competitive pricing. This article provides a comprehensive evaluation of the performance and cost-effectiveness of SKF bearings and TIMKEN bearings, aiding customers in making informed decisions.

Bearing Performance:

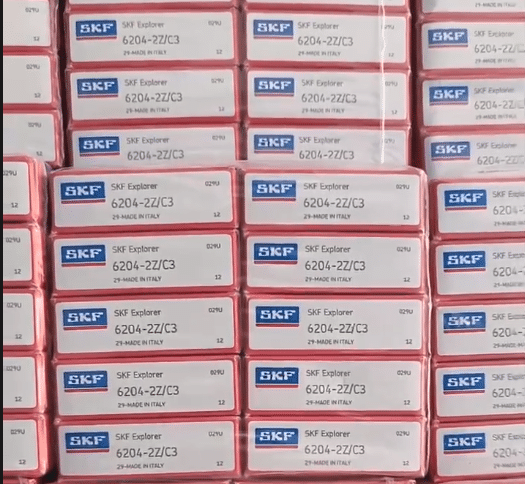

SKF Bearings:

SKF bearings are engineered to deliver superior performance, reliability, and efficiency in diverse applications. SKF achieves this through precision engineering, advanced materials, and innovative design solutions.

SKF bearings exhibit excellent load-carrying capacity, high-speed capability, and resistance to wear and fatigue. Whether it’s deep groove ball bearings, spherical roller bearings, or tapered roller bearings, SKF bearings excel in demanding operating conditions.

Additionally, SKF’s focus on lubrication technology ensures efficient lubricant distribution, reducing friction and minimizing wear on bearing surfaces. This contributes to extended service life, reduced maintenance requirements, and overall system efficiency.

TIMKEN Bearings:

TIMKEN bearings are renowned for their exceptional performance and durability, making them preferred choices for heavy-duty applications. TIMKEN specializes in tapered roller bearings, cylindrical roller bearings, and spherical roller bearings, engineered to withstand high loads and harsh environments.

TIMKEN bearings demonstrate superior load-carrying capacity, excellent speed capability, and resistance to wear and abrasion. TIMKEN’s precision engineering and advanced materials science ensure consistent performance and reliability in critical applications.

Moreover, TIMKEN’s application-specific designs and specialized coatings further enhance bearing performance and longevity, ensuring optimal operation under challenging conditions.

Cost-effectiveness:

SKF Bearings:

SKF bearings offer excellent value for money, combining high performance with competitive pricing. While SKF bearings may have a slightly higher initial cost compared to some competitors, their superior quality and extended service life result in lower total cost of ownership over the bearing’s lifecycle.

SKF’s focus on reliability and efficiency translates into reduced maintenance costs, minimized downtime, and increased productivity for customers. Additionally, SKF’s extensive distribution network and aftermarket support ensure timely availability of bearings and spare parts, further enhancing cost-effectiveness.

TIMKEN Bearings:

TIMKEN bearings provide exceptional value proposition, offering high performance at competitive prices. TIMKEN’s reputation for reliability and durability ensures that customers receive long-term benefits and cost savings.

Although TIMKEN bearings may have a slightly higher upfront cost, their superior quality and extended service life result in lower maintenance costs and reduced total cost of ownership. TIMKEN’s customer-centric approach and aftermarket support contribute to overall cost-effectiveness and customer satisfaction.

Conclusion:

In conclusion, both SKF bearings and TIMKEN bearings offer excellent performance and cost-effectiveness, catering to the diverse needs of industrial and automotive customers. While SKF excels in precision engineering and lubrication technology, TIMKEN specializes in durability and application-specific designs. By understanding the performance and cost-effectiveness characteristics of SKF and TIMKEN bearings, customers can select the most suitable bearing solution to optimize efficiency and profitability in their applications.

We support more information about Bearings. you can visit https://cmtgbearing.com. or email us info@cmtgbearing.com.