NSK Bearing and NTN Bearing are two prominent brands in the bearing industry, known for their high-quality products and innovative technologies. This article aims to provide a deeper understanding of the differences and advantages between NSK Bearing and NTN Bearing, shedding light on their unique features and strengths.

Technological Expertise:

NSK Bearing and NTN Bearing have extensive technological expertise and continually invest in research and development to enhance their bearing designs. NSK focuses on developing advanced materials, such as high-performance steels and ceramic balls, to improve bearing durability and performance. NTN, on the other hand, specializes in precision engineering, employing advanced manufacturing techniques to achieve superior dimensional accuracy and smooth operation.

Product Range:

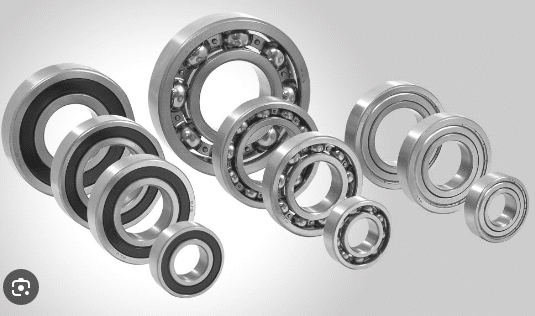

Both NSK Bearing and NTN Bearing offer a wide range of bearings to cater to diverse industrial applications. NSK provides a comprehensive portfolio of bearings, including deep groove ball bearings, angular contact bearings, cylindrical roller bearings, and more. NTN also offers a vast selection of bearings, encompassing ball bearings, roller bearings, and specialized bearings for specific industries such as automotive and aerospace.

Load Capacity and Performance:

NSK Bearing and NTN bearings exhibit differences in load capacity and performance characteristics. NSK bearings are renowned for their high load-carrying capacity, making them suitable for heavy-duty applications in industries such as mining and construction. NTN bearings, on the other hand, excel in precision applications that require low friction, high-speed operation, and accurate motion control.

Durability and Reliability:

Both NSK Bearing and NTN Bearing prioritize durability and reliability in their bearing designs. NSK implements advanced heat treatment processes and surface coatings to enhance bearing life and resist contamination. NTN focuses on quality control throughout the manufacturing process to ensure consistent performance and reliability. Both brands undergo rigorous testing to validate their bearings’ durability and reliability under various operating conditions.

Sealing and Lubrication:

NSK Bearing and NTN Bearing offer different sealing and lubrication solutions to meet specific application requirements. NSK bearings feature various sealing options, including contact seals and non-contact shields, to prevent ingress of contaminants and retain lubrication. NTN provides a range of advanced lubricants, including greases and oils, tailored for specific operating conditions, temperature ranges, and speeds.

Global Presence and Support:

Both NSK Bearing and NTN Bearing have a global presence and provide extensive customer support services. They offer technical expertise, application engineering support, and aftermarket services to assist customers in selecting the right bearings and resolving any issues. Their widespread distribution networks ensure prompt availability of products and support worldwide.

Conclusion:

In conclusion, NSK Bearing and NTN Bearing are distinguished brands in the bearing industry, each with its own unique features and advantages. NSK excels in high-load applications, offering advanced materials and technologies for enhanced durability and performance. NTN specializes in precision applications, emphasizing precision engineering and smooth operation. When choosing between NSK and NTN bearings, it is important to consider specific application requirements, load capacity, operating conditions, and support services to make an informed decision.

We support more information about Bearings. you can visit https://cmtgbearing.com. or email us info@cmtgbearing.com.