Maintenance costs can significantly impact the overall operational expenses of industrial equipment. NTN Bearings, a leading manufacturer, offers a wide range of high-quality bearings that can effectively reduce equipment maintenance costs. This article explores how NTN Bearings contribute to minimizing maintenance requirements, extending service intervals, and optimizing cost-efficiency. Through their innovative designs, superior durability, and reliable performance, NTN Bearings prove to be a cost-effective solution for businesses seeking to reduce maintenance expenses.

Enhanced Durability:

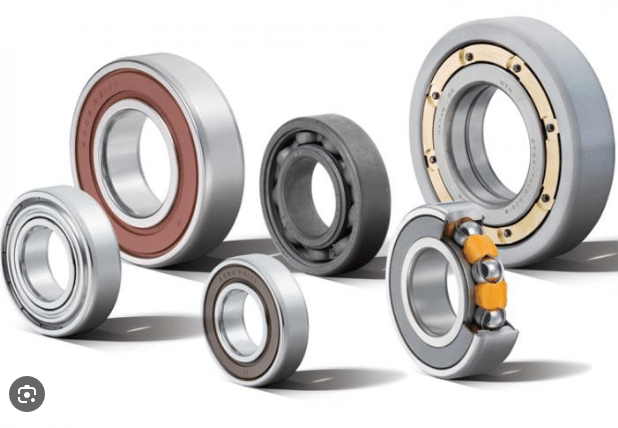

NTN Bearings are engineered with advanced materials and manufacturing processes that ensure exceptional durability. These bearings are designed to withstand heavy loads, high speeds, and harsh operating conditions without compromising performance. By offering superior resistance to wear, corrosion, and fatigue, NTN Bearings minimize the need for frequent replacements, reducing maintenance costs associated with bearing failure.

Efficient Lubrication Systems:

Proper lubrication is essential for the smooth operation and longevity of bearings. NTN Bearings incorporate efficient lubrication systems that optimize lubricant distribution and retention. These systems, including advanced grease formulations, sealed designs, and specialized lubrication methods, help to extend the service life of the bearings, reducing the frequency of lubrication and maintenance intervals.

Sealing Technologies:

Contamination is a common cause of premature bearing failure and increased maintenance costs. NTN Bearings employ advanced sealing technologies that effectively protect against the ingress of contaminants such as dust, moisture, and debris. With improved sealing performance, these bearings maintain their integrity, reducing the risk of unplanned maintenance and the associated costs.

Condition Monitoring and Predictive Maintenance:

NTN Bearings offer condition monitoring solutions that enable proactive maintenance practices. By employing sensor technologies, such as vibration analysis, temperature monitoring, and lubrication analysis, these bearings provide real-time insights into the health and performance of the equipment. This data allows for predictive maintenance scheduling, minimizing unplanned downtime, and optimizing maintenance costs.

Technical Expertise and Support:

NTN Bearings provides technical expertise and support to assist customers in optimizing their maintenance strategies. Their knowledgeable engineers can offer guidance on bearing selection, installation techniques, and maintenance best practices. By leveraging NTN’s expertise, businesses can implement proper maintenance procedures, reduce unnecessary repairs, and effectively manage maintenance costs.

Total Cost of Ownership Considerations:

NTN Bearings take into account the total cost of ownership when designing their products. By offering bearings with extended service life, reduced maintenance requirements, and enhanced reliability, NTN helps businesses optimize their maintenance budgets and achieve long-term cost savings. The initial investment in high-quality NTN Bearings is offset by the reduction in maintenance costs over the equipment’s lifespan.

Conclusion:

NTN Bearings prove to be a cost-effective choice for reducing equipment maintenance costs. Through their enhanced durability, efficient lubrication systems, advanced sealing technologies, and condition monitoring capabilities, these bearings minimize the frequency of maintenance, mitigate the risk of premature failures, and optimize cost-efficiency. By selecting NTN Bearings, businesses can significantly reduce their maintenance expenses while ensuring reliable and long-lasting performance of their equipment.

We support more information about Bearings. you can visit https://cmtgbearing.com. or email us info@cmtgbearing.com.

| NTN BEARINGS 61024 | NTN BEARINGS 61322 |

| NTN BEARINGS 61222 | NTN BEARINGS VARIOUS SELCTION MADE IN JAPAN |