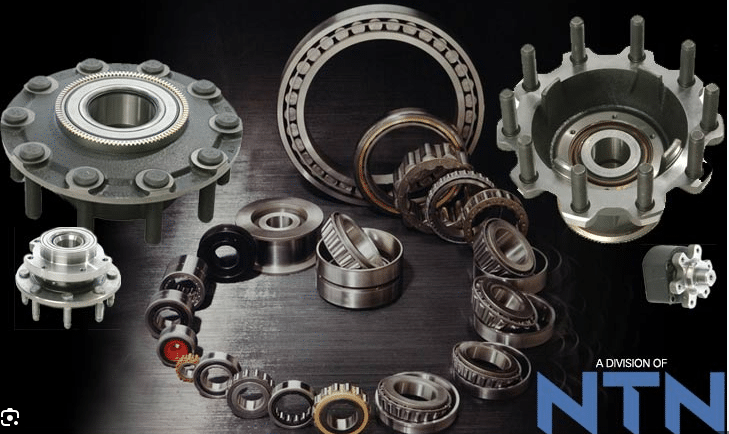

Precision and reliability are essential factors in the performance of bearings, and NTN Bearings is at the forefront of delivering advanced technologies to meet these requirements. With a focus on precision engineering, rigorous quality control, and continuous innovation, NTN Bearings ensures that their products provide exceptional accuracy and reliability in various industrial applications. This article delves into the NTN Bearing technology, highlighting the key factors that contribute to its precision and reliability, including advanced manufacturing processes, stringent quality assurance measures, optimized designs, and cutting-edge materials.

Advanced Manufacturing Processes:

NTN Bearings employs state-of-the-art manufacturing processes to achieve precision and consistency in their products. Utilizing cutting-edge machinery and computer-controlled production systems, NTN ensures the highest level of accuracy in bearing components. From precision grinding of raceways to ultra-precise assembly techniques, every step is carefully executed to meet stringent tolerances and deliver superior quality bearings.

Stringent Quality Assurance Measures:

To guarantee reliability, NTN Bearings implements stringent quality assurance measures throughout the manufacturing process. Advanced inspection techniques, including dimensional measurements, surface analysis, and performance testing, are employed to ensure that each bearing meets or exceeds industry standards. This comprehensive approach to quality control ensures that NTN Bearings consistently delivers products with exceptional precision and reliability.

Optimized Designs:

NTN Bearings continually strives to optimize bearing designs to maximize performance and reliability. Through extensive research and development efforts, NTN enhances bearing geometries, material compositions, and internal clearances to minimize friction, reduce wear, and enhance load-carrying capabilities. By optimizing designs, NTN Bearings achieves higher levels of precision and reliability, ensuring smooth operation and extended service life in various applications.

Cutting-Edge Materials:

The selection of materials plays a crucial role in the precision and reliability of NTN Bearings. NTN utilizes advanced materials, such as high-quality steel alloys and specialized heat treatments, to enhance the strength, durability, and fatigue resistance of their bearings. These materials undergo rigorous testing to ensure their suitability for demanding operating conditions. By using cutting-edge materials, NTN Bearings provides bearings that exhibit exceptional precision and reliability even under heavy loads and challenging environments.

Continuous Innovation:

NTN Bearings maintains a strong commitment to innovation, constantly seeking new technologies and advancements to improve their products’ precision and reliability. Through collaborations with research institutions, industry partners, and customer feedback, NTN stays at the forefront of bearing technology. This ongoing pursuit of innovation enables NTN to introduce novel features, such as advanced sealing solutions, lubrication systems, and bearing coatings, further enhancing precision and reliability.

Conclusion:

NTN Bearings’ commitment to precision and reliability is evident in their advanced manufacturing processes, stringent quality assurance measures, optimized designs, and utilization of cutting-edge materials. By incorporating these elements into their bearing technology, NTN ensures that their products provide exceptional accuracy, durability, and performance in a wide range of industrial applications. Whether in high-speed machinery, heavy-duty equipment, or precision instruments, NTN Bearings’ precision and reliability contribute to efficient operation, reduced downtime, and overall productivity gains. As industries continue to demand higher levels of precision and reliability, NTN Bearings remains a trusted partner, providing innovative solutions that meet and exceed their expectations.

We support more information about Bearings. you can visit https://cmtgbearing.com. or email us info@cmtgbearing.com.