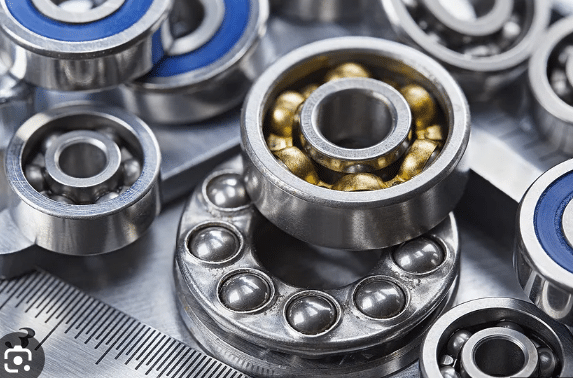

In the competitive bearing industry, product specifications play a critical role in determining the performance, reliability, and overall quality of bearings. SKF and FAG, as leading manufacturers, have established themselves as trusted brands known for their precision engineering and technical excellence. This article examines and compares the technical specifications of SKF and FAG bearings, shedding light on how these specifications influence product quality.

Importance of Product Specifications

Product specifications outline the critical features and performance capabilities of bearings. These specifications provide valuable information to customers, enabling them to select the most suitable bearings for their specific applications. Detailed technical specifications are a testament to a manufacturer’s commitment to meeting industry standards and delivering high-quality products.

SKF Bearings Technical Specifications

SKF has a comprehensive range of bearings, each designed to meet diverse industrial requirements. The company’s technical specifications encompass a wide array of factors, including bearing type, size, load capacity, speed rating, precision class, and operating temperature range.

SKF’s precision engineering is evident in the tight tolerances specified for their bearings, ensuring consistent performance and reduced friction. The use of advanced materials and specialized coatings enhances corrosion resistance and prolongs bearing life, contributing to superior product quality.

Moreover, SKF’s technical specifications for lubrication and sealing solutions optimize bearing performance under various operating conditions. Patented innovations such as sensor technologies and data analytics enable smart bearing solutions, allowing for predictive maintenance and real-time monitoring.

FAG Bearings Technical Specifications

FAG is renowned for its expertise in precision engineering and delivering bearings that excel in specialized applications. The company’s technical specifications encompass bearing dimensions, load ratings, accuracy classes, running accuracy, and noise levels.

FAG’s technical specifications highlight its focus on meeting industry-specific requirements, such as bearings designed for high-speed applications, extreme temperatures, and heavy-duty operations. The company’s stringent quality control measures ensure that bearings consistently meet or exceed the specified tolerances, contributing to their superior performance and reliability.

FAG’s technical specifications for lubrication and sealing solutions optimize bearing performance, enhancing their ability to withstand demanding operating conditions and extend service life.

Comparative Analysis of Product Specifications

4.1 Load Capacity and Speed Rating

Both SKF and FAG bearings offer a wide range of load capacities and speed ratings to cater to diverse industrial applications. The companies’ precision engineering and material selection contribute to the load-carrying capabilities of their bearings, ensuring reliable performance under varying loads and speeds.

4.2 Precision Class and Running Accuracy

SKF and FAG bearings specify different precision classes and running accuracies, reflecting their respective expertise in precision engineering. Customers can select bearings that meet their specific requirements for precision and accuracy, ensuring optimal performance in critical applications.

4.3 Operating Temperature Range

Both SKF and FAG bearings are engineered to withstand a broad temperature range. Their technical specifications outline the upper and lower temperature limits, ensuring that the bearings can operate effectively in diverse environmental conditions.

4.4 Lubrication and Sealing Solutions

SKF and FAG bearings offer a variety of lubrication and sealing options, allowing customers to select solutions tailored to their application needs. Proper lubrication and effective sealing are essential for ensuring the long-term reliability and performance of bearings.

Impact on Product Quality

The technical specifications of SKF and FAG bearings directly impact their product quality and reliability. Both companies’ stringent adherence to specified tolerances and quality control measures ensures consistent and predictable performance, contributing to the high-quality and durability of their bearings.

The use of advanced materials, specialized coatings, and smart technologies enhances the overall value and efficiency of SKF and FAG bearings, making them preferred choices in various industrial applications.

Conclusion

In conclusion, product specifications are crucial in determining the performance and quality of SKF and FAG bearings. The companies’ technical specifications showcase their dedication to precision engineering and meeting customer needs across diverse industries.

The comprehensive range of technical specifications, including load capacity, speed rating, precision class, and operating temperature range, allows customers to make informed decisions and select the most suitable bearings for their applications.

Through their commitment to delivering bearings that meet stringent technical specifications, SKF and FAG continue to solidify their positions as industry leaders and trusted providers of high-quality and reliable bearings.

We support more information about Bearings. you can visit https://cmtgbearing.com. or email us info@cmtgbearing.com.